PLW 8615 [Safety EL] - Highlights

View product

Exclusive to Miele

Smart two-pump technology

The heart of perfect results

Two-pump technology is at the heart of Miele’s PLW 86 model series. The variable-speed pump is particularly flexible regarding the basket coupling system. This pump adapts the wash pressure and required water to the specific requirements – high pressure facilitates the removal of stubborn soiling, while low pressure ensures complete wetting of the whole load. This guarantees minimum use of resources with outstanding wash results.

Conductivity monitoring

Safety through controls

Residues from chemical agents during the final rinse phase can compromise the reprocessing result. Conductivity monitoring of the wash water facilitates the detection of such residues and their reduction to a defined level through further rinsing. This means that the reprocessing is more reliable, more resource-friendly and also reproducible.

Spray arm monitoring

Safety through controls

For optimum reprocessing results, the rotation speed of the spray arms must always lie in a prescribed interval. Through the contact-free monitoring of all machine and basket spray arms, problems such as the build-up of foam or an obstructing load item can be detected early on. As a result, spray arm monitoring contributes to the reliable reproduction of the validated reprocessing quality.

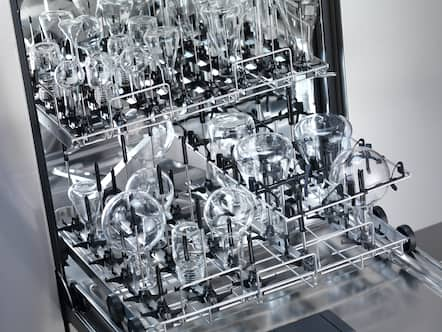

Modular load carriers

Versatile load carriers

The versatile load carriers from Miele Professional offer a wide array of possibilities with regard to loading. The load carriers can be flexibly adapted to the load items in just a few steps with a small number of load carriers in combination with some additional modules and inserts. This saves costs as well as space.

Programmable controls

Greater flexibility

The extensive range of options for specific needs are a particular advantage of programmable controls. Users can compile and save their own programmes. This ensures that the specific reprocessing requirements are met perfectly.