Compare

PG 8536 [ADP SST]

Washer-disinfector With feed pump for AD water.

- Performance/cycle, e.g. 66 narrow-necked glassware or 96 pipettes

- Highest level of flexibility - individually programmable controlsProgrammable controls

The programmable controls give the washer-disinfectors a high level of flexibility. The machines are already equipped with numerous programmes for all kinds of applications ex works. Authorised users can modify these programmes or upload their own programmes. - Safety - spray arm monitoring and automatic mobile unit recognitionFor a reliable result

Outstanding reprocessing results are achieved through spray arm monitoring, which immediately detects irregular spray pressure or any load blockages. In combination with automatic mobile unit recognition, the highest level of safety is guaranteed. By using a magnetic strip, the washer-disinfector recognises the different mobile unit types with their specific loads and automatically selects the appropriate reprocessing programme. - Perfect drying results - efficient hot air dryingEfficient drying

Active hot air drying is the optimum solution for hollow instruments or narrow-lumened laboratory glassware. The upstream H13 HEPA filter ensures optimum particle separation from the drying air. The filter is easily accessible via a side unit. - Total security - interface for process documentationProcess documentation

Safety through the clear documentation of all the reprocessing steps.

Product benefits

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Clear text display

Text display

Everything at a glance: The display shows everything as clear text in the country-specific language.

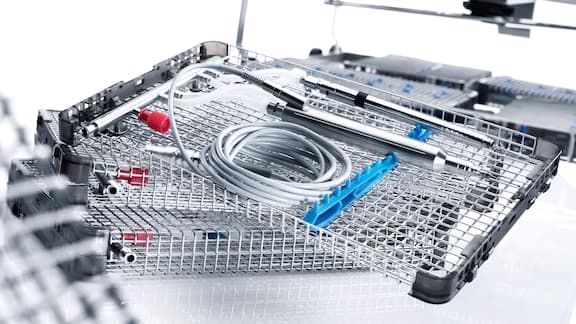

Large selection of components

Reprocess flexibly

Flexible and comprehensive components for optimum cleaning performance and a variety of reprocessing options.

Additional integrable dispenser pumps

Dispense practically and easily

For applications that require additional media, additional dispenser pumps can be integrated into the machine.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Product details

PG 8536 [ADP SST]

EAN 4002514859903 / Article number 62853625GB / Material number 07831490

EAN 4002514859903 / Article number 62853625GB / Material number 07831490

| DIN mesh trays per cycle [number] | 7 |

|---|---|

| MIS sets per cycle [number] | 2 |

| AN sets per cycle [number] | 2-3 |

| Narrow-necked glassware per cycle [number] | 66 |

| Pipettes per cycle [number] | 96 |

| Circulation pump, Qmax in l/min | 600 |

|---|---|

| Maximum final rinse temperature in °C | 93 |

| Wash cabinet usable capacity in l | 137 |

| Tested operating hours Note Our machines undergo intensive testing under laboratory conditions. The actual operating hours may vary depending on actual usage behaviour, maintenance and care of the machine. | 15000 |

| Electrical connection | 3N AC 400V 50HZ |

|---|---|

| Electric heater rating in kW | 9 |

| Total rated load in kW | 10.2 |

| Fuse rating in A | 16 |

| Length of mains connection cable in m Note The length refers to the supply lead on the outside of the appliance. | 1.6 |

| Cold water [number] | 1 |

|---|---|

| Cold water for steam condenser [number] | 1 |

| Hot water [number] Efficient hot water connection Connection to the warm water supply saves a lot of time and energy. | 1 |

| VEP – with feed pump for DI water [number] | 1 |

| Required flow pressure in kPa Note on ADP variants This value applies to cold, hot and DI water; however, it does not apply to DI water intake on ADP variants because these use a feed pump. | 250-1000 |

| Maximum delivery head for drain pump in cm | 100 |

| Integrated water softener | |

| Maximum water hardness (cold water/hot water) in mmol/l | 10.7 |

| Drain pump [DN] | 22 |

| Water protection system Waterproof System (WPS) Protection against flooding: In the event of problems, the system stops water intake automatically. | Waterproof system |

| Integrated drying unit | |

|---|---|

| Fan in kW | 0.3 |

| Heater element in kW | 2.3 |

| Total rated load in kW | 2.6 |

| Air throughput in m³/h | 60 |

| Temperature setting in 1 °C increments | 60-115 |

| Time setting in 1-minute increments | 1-240 |

| HEPA filter class | H14 Efficient hot air drying Efficient internal and external drying of the whole instrument using hot air filtered with a H14 HEPA filter. |

| HEPA filter filtration efficiency (in accordance with DIN EN 1822) in % | 99.995 |

| HEPA filter service life in h | 500 |

| External dimensions, net height in mm | 1175 |

|---|---|

| External dimensions, net width in mm | 900 |

| External dimensions, net depth in mm | 700 |

| External dimensions, gross height in mm Note Including packaging | 1380 |

| External dimensions, gross width in mm Note Including packaging | 1200 |

| External dimensions, gross depth in mm Note Including packaging | 800 |

| Wash cabinet, usable height in mm | 520 |

| Wash cabinet, usable width in mm | 530 |

| Wash cabinet, depth of upper basket in mm | 474 |

| Wash cabinet, depth of lower basket in mm | 520 |

| Net weight in kg | 177 |

| Gross weight in kg Note Including packaging | 208 |

| Emission sound pressure level in the workplace Emissions - sound pressure at workplace The emission sound pressure level depends on the programme and is a value given to the noise created by the machine. Miele Professional appliances have very low noise levels. | <lt/>70 dB(A) re 20 µPa |

|---|---|

| Heat dissipation into the room in MJ/h Heat output into the room During operation warm air is vented into the surrounding room. The released amount of heat/time depends on the set temperatures and the intensity of use. The stated maximum value can be used to control the temperature of the area or to calculate an increase in room temperature. | 1.62 |

| DES-VAR-TD | |

|---|---|

| DES-VAR-TD-AN | |

| VAR-TD-NR | |

| Inorganic | |

| Organic | |

| Plastics | |

| OPTHALMOLOGY | |

| ORTHOVARIO | |

| OXIVARIO | |

| OXIVARIO Plus | |

| SHOE-TD | |

| SPECIAL 93/10 | |

| CHEM-DISIN | |

| LAB-STANDARD | |

| LAB-UNIVERSAL | |

| LAB-INTENSIVE | |

| LAB-PIPETTES | |

| LAB-OIL |

| 1 dispenser pump for liquid cleaning agent | |

|---|---|

| 1 dispenser pump for neutralising agent | |

| Bellows-type dispenser pumps | |

| Additional integrated dispenser pumps (optional) | |

| Ultrasonic dispenser volume control | |

| Spray arm monitoring | |

| Conductivity monitoring (optional) | |

| Interface for process documentation | |

| Multi-component filter system | |

| Pump with high circulation rate | |

| Automatic mobile unit recognition | |

| Active drying | |

| Customer Service optical interface | |

| Setting options for process chemicals (4 x 5 l) | |

| Wash cabinet made from high-quality stainless steel (1.4301/304) | |

| Extensive components (option) |

| VDE (electrical safety) | |

|---|---|

| IP safety class according to EN 60529: IP 20 | |

| EN 61010-1 | |

| EN 61010-2-040 | |

| RoHS guideline 2011/65/EU |

Additional accessories and consumables

Find additional accessories and consumables to go with this product

Additional accessories for laboratory technology

Find here the accessories that can be bought additionally for this product.

Additional consumables for laboratory technology

Find here the consumables that can be bought additionally for this product.

Additional components for medical technology

Find here the components that can be bought additionally for this product.